Mortar bonds bricks or other masonry units and strengthens walls and other structures. Type S mortar mix, in particular, is load-bearing and performs extremely well to withstand pressure from soil, wind, and seismic loads.

However, there are other types of mortar mixes—types N, O, and M—that are mixed with different ratios of cement, lime, and sand to produce specific performance characteristics, emphasizing flexibility, bonding properties, and compressive strength. The best mortar types and their use depend on the application and the design specifications for the project.

Types of Mortar

Types of mortars are generally categorized into lime mortars, cement mortars, and specific types like S, N, O, M, and K types. Each type is composed differently, each with varying strengths and applications.

Types of Mortar by Composition

Mortars have different compositions that create the paste-like mixtures used for different applications vs. S, N, O, M, and K types made with varying parts of cement and sand. Here are some types of mortar by composition:

- Lime mortar: This mortar type is not used anymore because Portland cement is more common.

- Cement mortar: Cement mortar is a basic mix of cement, sand, and water. Aerated cement mortar adds a foaming agent to create a lighter, thermal, and acoustic insulation material used for building materials.

- Surkhi mortar: This mortar's sand is replaced with finely powdered burnt clay and used for water-resistant building applications.

- Gauged mortar: The formulation of cement, lime, and sand allows for movement and is used for various masonry (bricklaying, foundations, repairs) for sensitive historic buildings.

- Thin-set mortar: This thinner mortar, composed of cement, sand, and water, is used for tile but is not fit for use with heavier bricks or stones.

- Mud mortar: Mud replaces lime in this lower-cost mortar. It is used to bind building products, like stones, bricks, or tiles.

- Epoxy mortar: This newer mortar type is waterproof, stain-resistant, consists of epoxy resins and solvents, cures fast, and is preferred for use in tile work.

- Gypsum mortar: This type of mortar, made from gypsum, sand, and water, is used to plaster walls and ceilings because it's smooth to apply and fast-setting.

- Packing mortar: This is another commercially used mortar that usually combines cement, sand, and loam. It is extremely strong, and many oil wells are built with this type of mortar.

- Specialty mortar: If you're working on a project such as a fire pit, fireplace, or chimney, you will need to use a special high-heat mortar, also known as refractory mortar, which is formulated to handle high temperatures. Chemical-resistant mortar is another specialty type formulated to withstand exposure to harsh and corrosive chemicals.

- Heavy- and lightweight mortar: These mortars use heavy- or light-density aggregates for special applications. Heavy-weight mortar can be used for commercial areas where radiation reduction is necessary. Lightweight mortar is used for soundproofing and thermal applications.

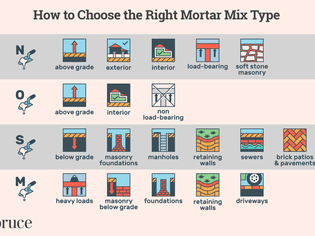

Type S Mortar Mix

Type S mortar is the common choice for many below-grade applications, such as the following:

- Masonry foundations

- Manholes

- Retaining walls

- Sewers

- At-grade projects like brick patios and walkways

Type S mortar mix offers high compressive strength of over 1,800 psi and high-tensile bond strength. It is a load-bearing mix that withstands pressure from the structure that it is bearing, as well as pressure from soil, wind, and seismic loads.

The most common ratio formula for Type S mortar is two parts Portland cement, one part hydrated lime, and nine parts sand. It can be mixed at different ratios for strengths reaching 2,300 and 3,000 psi. Lime gives type S its water-resistant properties, as opposed to mortar mixes with lower ratios of lime.

Type N Mortar Mix

Type N is the mortar most often used by homeowners and is the best choice for general applications. Type N mortar mix is useful for the following:

- Above-grade walls (including stone veneer), exterior applications exposed to severe weather and high heat

- Interior load-bearing installations

- Soft stone masonry (such as limestone)

Type N mortar mix has a medium compressive strength and is composed of one part Portland cement, one part lime, and six parts sand. It typically achieves 750 pounds per square inch (psi) strength within 28 days.

Type O Mortar Mix

Type O mortar mix has relatively low compressive strength (at about 350 psi) As such, it is used primarily for interior, above-grade, non-load–bearing walls.

Type O mortar mix can be used as an alternative to Type N for some interior applications, but its exterior use is limited due to its low structural capacity.

Type O mortar mix is not recommended in areas subjected to high winds. However, type O mortar mix is ideal for repointing and similar repair work on existing structures, due to its consistency and ease of application.

Type M Mortar Mix

Type M mortar mix has the highest amount of Portland cement and is recommended for heavy loads and below-grade applications, such as:

- Building foundations

- Retaining walls

- Driveways

While type M mortar provides at least 2,500 psi of compressive strength, it offers relatively poor adhesion and sealing properties, making it unsuitable for many exposed applications. Type M is preferred for use with natural stone because it offers similar strength to that of stone.

Type K Mortar Mix

Type K mortar is rarely used for new construction. Because of its softness, type K is primarily used for restoring the masonry on historic or ancient buildings that require a special mix that is not significantly stronger than the existing masonry. It offers a very low compressive strength of only about 75 psi.

- Which type of mortar is the strongest?

The strongest type of mortar is type M mortar mix. This mortar contains the most cement in its ratio, making it ideal for heavy applications like foundations and retaining walls.

Is thinset mortar as strong as concrete?Though both thinset and concrete contain cement, thinset mortar is not as strong as concrete. Thinset bonds to tile, and has a less compressive strength compared to concrete. Concrete is used for structural projects.

Does adding lime to a mortar mix make the mortar stronger?Yes, adding lime to mortar makes the mortar crack-resistant. Lime expands when it becomes hydrated, which adds to its strength.

Recommended Articles

PAINTING

PAINTINGWe Asked a Pro Painter For His Secret to a Seamless Paint Job Every Time—And We’re Obsessed

While painting a room isn’t necessarily a difficult DIY job, it’s not always easy—how many coats does one wall need again? There are a few critical ways to prepare before you get started on your paint

SMALL-SPACES

SMALL-SPACES11 Easy Ways to Make a Small Room Look Bigger

You may lament the lack of space if you're in the process of decorating a small room, but there are plenty of reasons why small is better: small spaces are easier to decorate, easier to keep clean, an

INTERIOR-DECORATING

INTERIOR-DECORATINGBerber Carpet: Pros and Cons, Cost, Durability, and More

Carpeting adds cushion, warms up a room in the winter, and offers a safe and comfortable spot for children to play. Of the many types of carpeting, Berber carpet is one of the most popular options bec

INTERIOR-REMODEL-AND-REPAIR

INTERIOR-REMODEL-AND-REPAIRI'm a New Homeowner, and These Are the 6 Best Renos I Did This Year

Renovating a home has been a dream of mine for over a decade. When my husband and I were finally in a position to buy our first home earlier this year, we were thrilled to find a house that had just e

INTERIOR-REMODEL-AND-REPAIR

INTERIOR-REMODEL-AND-REPAIR7 Home DIY Projects You Can Do for Less Than $100—But Make a Big Difference

There are a number of budget-friendly home upgrades you can make for an instant refresh.Replacing kitchen faucets, cabinet hardware, electrical switches, and lighting all go a long way.Painting, insta

HOME-IMPROVEMENT

HOME-IMPROVEMENTHow to Use Cement Backer Board

Cement backer board is an inexpensive, convenient building material that makes tiling, flooring, and countertop projects go faster and look better in the end. Most importantly, cement backer board co

EXTERIOR-REMODEL-AND-REPAIR

EXTERIOR-REMODEL-AND-REPAIR8 Budget-Friendly Exterior Projects for Instant Curb Appeal, Approved by Reno Pros

Upgrading your home's curb appeal can be done on a budget with a few simple DIY projects.Painting, replacing house numbers and light fixtures, and updating hardware can be done quickly.Larger-scale pr

EXTERIOR-REMODEL-AND-REPAIR

EXTERIOR-REMODEL-AND-REPAIRWant a Lower Energy Bill This Fall? Experts Say You Should Do One Task While It’s Still Warm

Key Points Sealing gaps around windows and doors before fall can cut energy bills by up to 20% and prevent moisture damage.Experts say doing it early makes fixes easier and improves heating efficiency